Introduction :

When selecting bearings for any purpose, ultimately you want to be certain of achieving the required level of equipment performance – and at the lowest possible cost Robustness also is very important because the conditions in which your equipment is assembled, operated and maintained may not be precisely known and may, in fact, vary over time.

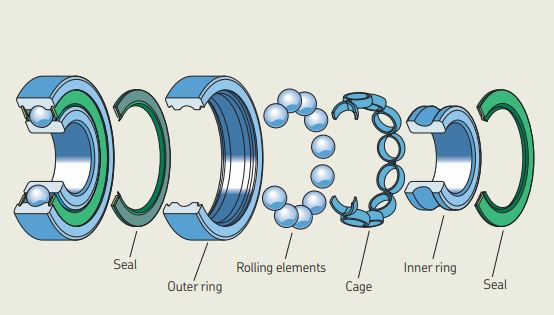

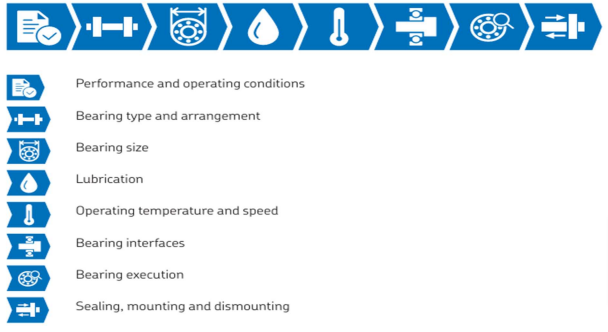

In addition to the bearing rating life, there are key factors you must consider when put ting together the

bearing specifications for an application as shown in figure.

To help evaluate these key factors, we recommend following the selection process shown in above figure. The process provides a straightforward step-by-step approach that shows the general relationship between each step by clearly defining and naming the steps in this way, it should be easier to find information on a specific topic in reality, however, you will find interdependencies that require you to loop back and forth between the steps. Other Factors to be considered are,

- Lubricant and supply method

- Shaft and housing fits

- Bearing clearance class

- Cage material and guidance

- Dimensional stability

- Precision requirements

- Bearing sealing

- Mounting and Maintenance

We will see the step-by-step process of bearing selection in coming section.

Bearing Performance and Operating Condition :

An application can set various Performance requirements on the bearing solution. Common factors include:

1 – bearing life

2 – . speed capability and ability to withstand applied acceleration levels

3 – precision of the radial and axial position of the shaft

4 – ability to cope with low or high temperatures or temperature gradients

5 – generated noise and vibration levels

You should evaluate the operating conditions in as much detail as possible. The most important operating parameters are:

1 – load

2 – speed

3 – temperature

4 – lubricant and lubricant cleanliness

2 . Examine Bearing Type and Size :

Below factors to be considered while deciding bearing type and size for any application.

- Load (Direction, Size, Oscillation, Shock)

- Rotating Speed

- Sound and Torque

- Misalignment and Rigidity

- Axial Position

- Mounting and Dismounting

- Environment (Vibration and Shock)

3. Examine Bearing Dimension :

Most Common Factors to be considered while deciding bearing dimensions are listed below.

- Space for Bearing

- Desired Service Life

- Rotation Speed

- Standard parts available

4. Examine Accuracy :

Common factors to be considered while examine accuracy are listed below

- Deflection of Rotating Ring

- Vibration from rotation

- Rotation per minute

- Torque and its fluctuation

5. Examine Shaft and Housing Fits :

While examining shaft and housing fits attention on below factors is needed.

- Determine which ring is rotating

- Properties and size of load

- Housing and shaft construction

- Material ambient temperature

6. Examine Internal Clearance :

Examination of common factors to be needed are,

- Clearance reduction by fits

- Misalignment

- Temperature difference between rings

- Preloads

7. Examine cage material and type :

Examination needed are,

- Rotating Speed

- Sound and Vibration

- Torque Fluctuation

8. Examine Lubrication and Sealing :

This part is very important for enhancement of bearing life and its performance. Most common factors to be examined are,

- Operating Temperature

- Rotating speed

- Lubricant and delivery system

- Special atmospheric construction (Water, Chemicals)

- Material of seal device

9. Examine Ring and Rolling Element Material :

The factors which play an important role in determining ring and rolling material of the bearing are listed below as per application

- Operating Temperature

- Atmospheric condition (Corrosive)

- Impact / Vibratory load conditions

10. Examine Installation and Maintenance :

Examination of bearing installation and maintenance process is very important as it saves time during. Common factors to be examined are,

- Dimensions for assembly clearances

- Procedures for assembly

- Dismounting parts

- Accessories for mounting

Above are the 10 important steps which plays an important role in bearing selection process. While there is no “BEST” procedure available to select optimum bearing for the particular application, above

10 steps give manufacturer or end user an idea based on the establishment of priorities for the required bearing characteristics.

Conclusion :

So, by analysing the above information we can clearly understand that selection of bearing is very important step, if implemented carefully and correctly can enhance bearing performance, bearing life and ultimately quality of finished goods produced by that machine. It also helps manufacturer or end user to cut down break down time of the machine and maintenance cost of the machine and increasing the productivity.

Actionable Advice :

We at KEC Bearings Pvt Ltd firmly believes that product dispatched from the plant must perform above par level at the customer’s end. For that we have “KEC Application Engineering Service”, in which we are assisting end users and provides expertise to help and support our customers with their technical needs.

By following step by step application analysis process and using our calculations, our application engineer can evaluate correct bearing type and size, and other requirements such as lubrication, fits and sealing, in order to obtain the right application solution and achieve reliable rotating equipment performance. This service is available at below mentioned contact details,

Contact Details :

KEC Bearings Pvt Ltd

G-2408A, F2 Road, Almighty Gate, Lodhika GIDC, Metoda – 360021, Rajkot, Gujarat (INDIA)

Email: sales@kecbearings.com

WhatsApp: +91 9330 96 9330

Website: www.kecbearings.com