Introduction

In paper mill operations, machinery faces extreme demands, including high speeds, heavy loads, and exposure to challenging environmental conditions such as humidity, dust, and chemical exposure. To ensure reliability and efficiency in such an environment, spherical roller bearings (SRBs) have become indispensable.

This blog explores the applications, benefits, and considerations of using spherical roller bearings in paper mills.

Why Spherical Roller Bearings?

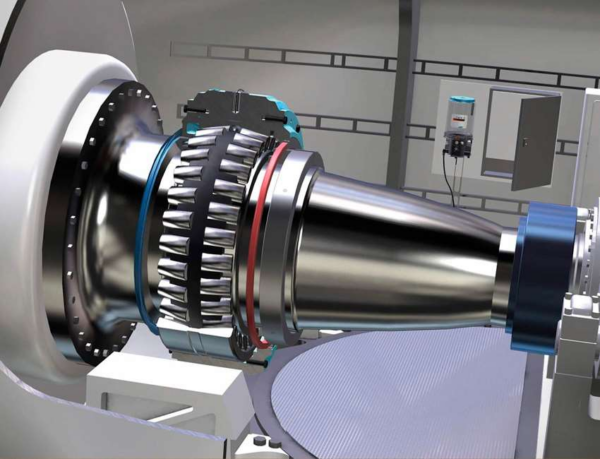

Spherical roller bearings are designed to handle heavy radial and axial loads simultaneously, making them ideal for the high-stress conditions found in paper mills. Their self-aligning feature also allows them to compensate for misalignment caused by shaft deflection or installation errors, ensuring operational reliability.

Key Applications in Paper Mills

- Dryer Sections:

o Challenge: High temperatures, variable loads, and exposure to steam.

o Solution: SRBs with heat-resistant materials and high load capacities ensure smooth operation under thermal stress and mechanical strain. - Calendar Rolls:

o Challenge: Precise alignment and handling significant radial and axial forces.

o Solution: The self-aligning capability of SRBs accommodates shaft deflections, ensuring uniform paper thickness and quality. - Press Sections:

o Challenge: Heavy loads from pressing rollers and constant exposure to water.

o Solution: SRBs with enhanced sealing systems prevent contamination and support extended bearing life in wet conditions. - Stock Preparation Equipment:

o Challenge: Vibration and inconsistent loads from pulpers and refiners.

o Solution: The robust design of SRBs absorbs vibrations and handles shock loads effectively.

Benefits of Spherical Roller Bearings in Paper Mills

- High Load-Bearing Capacity:

SRBs are engineered to handle the heavy loads and variable forces encountered in the demanding environment of a paper mill. - Self-Alignment Capability:

Misalignments caused by thermal expansion or installation inaccuracies are easily compensated, reducing the risk of premature failure. - Enhanced Durability:

Bearings designed with specialized materials and coatings resist corrosion, wear, and the ingress of contaminants like water and dust. - Reduced Downtime:

Long service life and reliability translate to fewer maintenance intervals, minimizing costly downtime. - Energy Efficiency:

Optimized internal designs reduce friction, contributing to energy savings over prolonged operation.

Selection Considerations

When choosing spherical roller bearings for a paper mill, consider the following factors:

- Load and Speed Requirements: Ensure the bearing can handle the specific load and speed combinations of the application.

- Temperature Resistance: Bearings with specialized heat treatments or lubricants are essential for high-temperature sections like dryers.

- Sealing and Lubrication: Select bearings with appropriate sealing solutions to prevent contamination and ensure proper lubrication.

- Material Selection: Stainless steel or coated bearings may be necessary for corrosive environments.

Future Trends in Spherical Roller Bearings

- Smart Bearings:

Integration of IoT-enabled sensors for real-time monitoring of temperature, vibration, and load to predict failures and schedule maintenance. - Advanced Materials:

New materials and coatings for improved resistance to wear and corrosion, extending bearing life in harsh environments. - Energy-Efficient Designs:

Innovations in internal geometry to further reduce friction and energy consumption.

Conclusion

Spherical roller bearings are a cornerstone of reliable operation in paper mills, providing the durability and adaptability required for demanding applications. By selecting the right bearings and maintaining them properly, operators can ensure optimal performance, improved productivity, and reduced downtime.

For those in the paper industry, investing in high-quality SRBs tailored to their operational needs is not just a choice—it’s a necessity.

Actionable Advice

At KEC Bearings we provide various kind of spherical roller bearings for various application and for various designs. It is very important that we use correct type of bearing with correct understanding of application parameters and bearing features. For the various application and bearing related features follow our You tube channel.

Contact Us

KEC Bearings Pvt Ltd

G-2408A, F2 Road, Almighty Gate, Lodhika GIDC, Metoda – 360021, Rajkot, Gujarat (INDIA)

Website: www.kecbearings.com

Email: sales@kecbearings.com

WhatsApp: +91 9330 96 9330