Introduction :

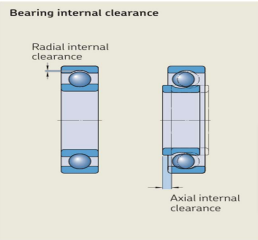

Bearing internal clearance is defined as the total distance through which one bearing ring can be moved relative to the other in the radial direction (radial internal clearance) or in the axial direction (axial internal clearance).

Internal clearance whether its radial or axial plays a very important role in the bearing life, performance and efficiency.

To define and install bearing with correct internal clearance is very important. Why it is important that we will see further with the content of this blog

Internal Clearance Vs Operating Clearance :

In almost all applications, the initial clearance in a bearing is greater than its operating clearance. The difference is mainly caused by two effects:

- Bearings are typically mounted with an interference fit on the shaft or in the housing. The expansion of the inner ring or the compression of the outer ring reduces the internal clearance.

- expansion of the inner ring or the compression of the outer ring reduces the internal clearance. Bearings generate heat in operation. Differential thermal expansion of the bearing and mating components influences the internal clearance.

Different types of Clearances :

To enable selection of the appropriate initial internal clearance to achieve the desired operational internal clearance, bearings are available in different clearance classes. ISO has established five clearance classes for many bearing types. Bearing manufacturer uses designation suffixes to indicate when the bearing internal clearance differs from Normal as shown in figure beside.

We can use different types of clearances used in bearings in different types of applications and with reference of fits that is used in shaft and housing.

Importance of Internal Clearance :

It is very important for the bearing performance that we choose correct bearing internal clearance depend upon fits of the shaft and housing with the bearings outer dimension and inner dimension. Generally, we have 2 types of fits in the bearing mounting i.e. loose fit and interference fit. Mostly bearings are mounted with interference fit which reduces bearing original internal clearance. While in loose fit bearing original internal clearance will not change as much. Now question is “Why it is important to choose bearing with correct internal clearance??” that we will discuss in next section.

For example, we have loose fit and we are going for the C3 or C4 Internal clearance in the bearing then our operating internal clearance will be same as original after mounting of bearing which results in too loose fit. Too loose fit will cause excessive vibration level and excessive noise level in the bearing. Because of that there is a chance that or bearing will not perform up to the mark and bearing failure will occur prematurely.

Take another example of Interference fit, if we choose bearing with original internal clearance of C2 or Normal and we have interference fit while mounting of the bearing. Then after mounting of the bearing our operating internal clearance will be reduced to below zero level (Pre load bearing) which will cause generation of excessive heat in the bearing while operating. Operating temperature of the bearing goes beyond the tolerance level and bearing will fail immediately.

During failure of the bearing, it may happen that it will damages other tools of the machine around it if not properly taken care of or continuously running after bearing failure which will cause/add additional maintenance cost.

Measurement of Clearance with Feeler Gauge :

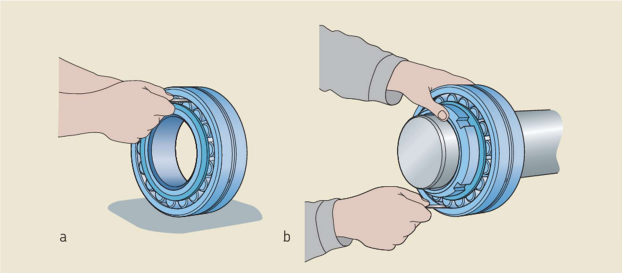

A feeler gauge is most often used to measure the radial internal clearance in the medium and large size spherical roller bearings before and after mounting as shown in figure that is before and after mounting. Before measuring, rotate the inner or outer ring a few times. Make sure that both bearing rings and the roller complement are centrically arranged relative to each other.

To start, select a feeler gauge blade that is slightly thinner than the minimum value for initial bearing clearance. When measuring, move the blade back and forth between the middle of the roller and raceway. Repeat this procedure using a thicker blade each time until you can feel a slight resistance between the blade and roller. To confirm the value, rotate the inner ring 180 degrees and measure again. Take measurements between:

- The outer ring and uppermost roller, before mounƟng († fig. a)

- The outer ring and lowest roller, after mounting († fig. b)

For large bearings, especially those having a rather thin-walled outer ring, the measurements are affected by the elastic deformation of the rings, caused by the weight of the bearing or the force to draw the feeler gauge blade through the gap between the raceway and an unloaded roller. To establish the “true” clearance before and after mounting, use the following procedure

- Measure the clearance “c” at the 12 o’clock position for a standing bearing or at the 6 o’clock position for an unmounted bearing hanging from the shaft.

- Measure the clearances “a” at the 9 o’clock position and “b” at the 3 o’clock position without moving the bearing.

- Obtain the “true” radial internal clearance with relatively good accuracy from 0,5 (a + b + c).

Conclusion :

It is highly recommended that person who are responsible for mounting and dismounting of the bearings should have knowledge of bearing internal clearance and clearance reduction. For example, while mounting bearing with taper bore, he/she should know up to which extent lock nut of the bearing should be tighten to have best bearing life and performance. He/she should have taken training about measuring bearing internal clearance before. During and after mounting of the bearings.

Actionable Advice :

We at KEC Bearings firmly believe that customer of KEC bearing must have expected bearing life and better machine utilisation with lesser maintenance cost. We are manufacturer of industrial bearings for last 25 years and also providing solutions regarding all the industrial problems regarding bearings. So contact us if you fed up with the bearing problems in your industry on following details

Contact Details :

KEC Bearings Pvt Ltd

G-2408A, F2 Road, Almighty Gate, Lodhika GIDC, Metoda – 360021, Rajkot, Gujarat (INDIA)

Email: sales@kecbearings.com

WhatsApp: +91 9330 96 9330

Website: www.kecbearings.com