Introduction :

In the current industry scenario, nobody wants to have Ideal machines at their plants. So, it is very important to have good maintenance practices at our company to have lesser breakdown time and more efficient machine output. Roller bearing plays a very important role in the operation of the machine.

cRolling bearings are reliable machine elements that can provide long service life, provided they are properly mounted and maintained. Proper mounting calls for experience as well as care, cleanliness, accuracy, the correct mounting method and the use of appropriate tools for the job

There are some easy steps to follow to have longer service life of the bearings and have lesser breakdown time of the machines. which we will discuss in this blog.

Planning :

It is very important to have correct planning for the mounting of the bearings. Prior to mounting we should properly check the drawings or instruction which will help us to have smooth process like having correct order to assemble components, correct bearing size, type and variant, correct grade of lubricants and qty, appropriate mounting method and related tools. Mounting method and related tools should be dependent on size of the bearing.

Cleanliness :

Cleanliness is essential to long bearing service life. Cleanliness begins in the storage room. Store bearings in a cool, dry area, on shelves that are not subjected to vibrations from adjacent machinery. Do not open the bearing package until it is time to install the bearing. Whenever possible, install bearings in a dry, dust-free area, away from metalworking or other machines producing swarf and dust. Make sure that the bearings and all mating parts, including the lubricant, are clean and free from damaging contaminants.

Removing the preservative from new bearings :

Bearings should be left in their original packages until immediately before mounting so that they will not be exposed to any contaminants, especially dirt. Normally, the preservative applied to new bearings does not need to be completely removed. It is only necessary to wipe off the outside diameter and bore surfaces.

Safety :

To minimize the chance of injury, when handling or mounting bearings:

-

- Always wear gloves, especially when handling heated bearings or working with lubricants.

-

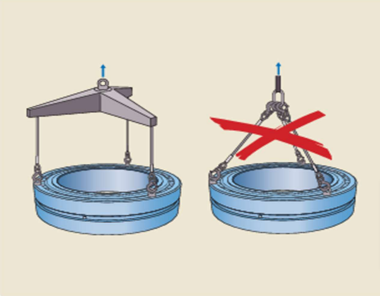

- Always use appropriate lifting or carrying tools.

-

- Never strike the bearing directly with any hard object such as a steel hammer or a chisel.

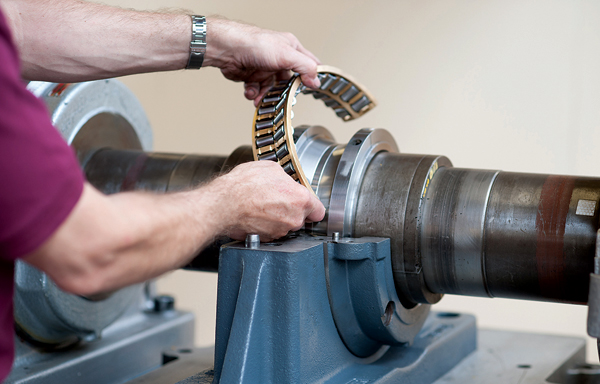

Bearing handling :

It is recommended using gloves as well as carrying and lifting tools that have been specially designed for mounting bearings. In addition to being a safety issue, using the proper tools will save time and effort. When handling hot or oily bearings, it is recommended wearing the appropriate heat or oil resistant gloves. Heated bearings and larger, heavier bearings can be difficult for one or two persons to handle safely. In these instances, satisfactory equipment for lifting and transporting the bearing should be used.

Bearing internal clearance :

A feeler gauge is most often used to measure the radial internal clearance in medium-size and large spherical roller bearings, before, during and after mounting. Before measuring, rotate the inner or outer ring a few times. Make sure that both bearing rings and the roller complement are centrically arranged relative to each other.

When measuring, move the blade back and forth between the middle of the roller and raceway. Repeat this procedure using a thicker blade each time until you can feel a slight resistance between the blade and roller. To confirm the value, rotate the inner ring 180 degrees and measure again. Take measurements between:

-

- the outer ring and uppermost roller, before mounƟng († fig. a)

-

- the outer ring and lowest roller, aŌer mounƟng († fig. b)

Bearing Mounting Methods :

-

- Cold Mounting

-

- Hot Mounting

Cold Mounting :

For cold mounting, there is a choice of methods:

-

- Mechanical methods: Mechanical methods are usually used to drive small bearings with a cylindrical or tapered bore onto a shaft or into a housing. The other three methods are only used to drive up bearings with a tapered bore onto a tapered seat.

-

- The oil injection method: Using the oil injection method can save considerable effort when mounting a bearing with a tapered bore. With this method, oil under high pressure is injected between the bearing bore and its seat to form an oil film. This oil film separates the mating surfaces and appreciably reduces the friction between them. Provided the application has been prepared for oil injection, this method can be used to mount a bearing: on a tapered shaft, on an adapter sleeve, on a withdrawal sleeve.

-

- Measuring inner ring expansion (Sensor Mount): it is used to mount bigger size bearings like bearing diameter >340 mm. Sensor Mount uses a sensor, imbedded in the bearing inner ring, and a dedicated hand-held indicator. The indicator processes the information from the sensor. Inner ring expansion is displayed as the relationship between the clearance reduction (µm) and the bearing bore diameter (mm). The value 0.450 shown on the indicator display is a common limit for bearings operating under normal conditions.

Hot Mounting :

The requisite difference in temperature between the bearing ring and shaft or housing depends on the degree of interference and the diameter of the bearing seat. When heating bearings, temperature control is essential:

-

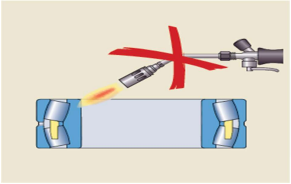

- Do not heat open bearings to more than 120 °C (250 °F).

-

- Do not heat-sealed bearings above 80 °C (175 °F) because of their grease fill and/or seal material.

For housings, a moderate increase in temperature, from 20 up to 50 °C (35 up to 90 °F), is normally sufficient, since the degree of interference is seldom large. Once a bearing has been heated, the objective is to get that bearing in place, up against its shoulder as quickly as possible and keep it there until the bearing has cooled.

To do this, it is recommended using a bearing handling tool and lifting tackle, especially when mounting medium size and large bearings.

When mounting a bearing, never strike it directly with any hard object such as a steel hammer or a chisel, and never apply the mounting force through the rolling elements. To heat a bearing or housing to the proper temperature quickly and safely, Market offers a wide assortment of heaters. Never heat a bearing using an open flame as shown in fig.

Conclusion :

So, it is recommended to use standard methods and tools to mount bearings to optimise its performance and have extended and efficient bearing life and lesser breakdown time of the machines. It is also appreciable to train and educate the persons directly or indirectly connected with the process with the time-to-time training and educational sessions by experts. It will not only enhance their skill sets but also improve their performance and efficiency in their work and ultimately final output of the machine.

Actionable Advice :

We at KEC Bearings Pvt Ltd, educate end users of our product about usages of our product in correct way and let them enjoy the best performance our products. We believe in solving industry related problems from their roots by enhancing skill set of our end users. We proudly introduced ourselves a solution provider rather than manufacturer. Feel free to contact us on below mentioned details for any further solution,

Contact Details :

KEC Bearings Pvt Ltd

G-2408A, F2 Road, Almighty Gate, Lodhika GIDC, Metoda – 360021, Rajkot, Gujarat (INDIA)

Email: sales@kecbearings.com

WhatsApp: +91 9330 96 9330

Website: www.kecbearings.com