KEC - Leading firm for Cylindrical Roller Bearings India

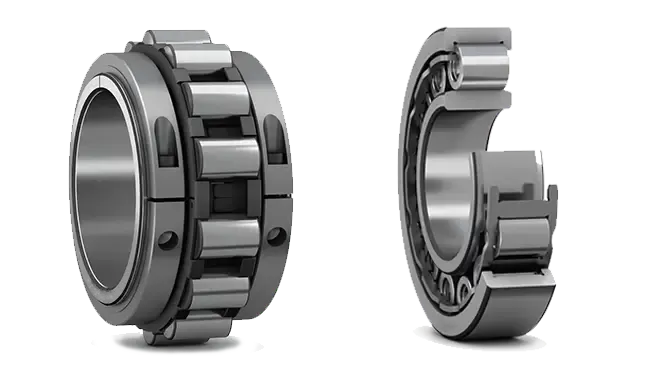

Cylindrical Roller Bearings

Applications

- Mining and Quarrying Equipment

- Construction Machinery

- Steel Industry

- Power Generation

- Agricultural Machinery

- Marine Applications

- Automotive

- Railways

- Industrial Fans and Blowers

- Paper and Pulp Industry

Contact For OEM supply

An Original equipment manufacturer (OEM) is a company that supplies components that are used in th production of goods by other manufacturers.

KEC BEARINGS proudly presents our premium range of Cylindrical Roller Bearings, designed to deliver superior performance and reliability in a variety of industrial applications. Our Cylindrical Roller Bearings are meticulously engineered from high-quality bearing steel, ensuring exceptional durability and longevity.

These bearings are ideal for applications requiring high radial load capacity and minimal friction. The unique design of our Cylindrical Roller Bearings allows them to accommodate heavy loads and high-speed rotations, making them perfect for use in heavy machinery, automotive applications, and industrial gearboxes.

What do you understand by cylindrical roller bearing?

Cylindrical bearings are straight in length on both the outside and the inside. And they sit perfectly within the structure. Bearings like these are utilized to provide support for spinning components and to allow movement seamlessly. Cylindrical bearings are easy to install because their easy design only requires a simple press connection. It reduces the chances of any damage occurring during the installation process. They are thin, which saves space and reduces weight, and the diameters of the cylindrical bearings can differ depending on the application and the customer’s requirements.

Bearings with exceptional functionality are what KEC manufactures. Being a Cylindrical Roller Bearing Company, it is known as the leading manufacturer of bearings for use in a variety of businesses all over the globe. Outer and inner rings, rectangular rollers, and a cage are the components that make up each of our bearings. They are an excellent choice for the various equipment that operate at fast velocities and are subject to significant rotational pressures.

Key Features

Self-Aligning Capability

Automatically adjusts to misalignment.

High-Quality Materials

Made from premium steel for superior performance.

Robust Design

Suitable for harsh environments and demanding applications.

Long Service Life

Enhanced durability and resistance to wear.

Low Friction

Reduces operating temperature and improves efficiency.

Single Row

Double Row

Discover detailed specifications, features, and benefits of our entire range of products by downloading our comprehensive brochure. Get in-depth information on applications, technical data, and more to help you make the best decision for your needs.

Toughness with Precision Guaranteed

Checkout Frequently Asked Questions

Find answers to common questions about our Cylindrical Roller Bearing, including their applications, specifications, and maintenance.

Regular maintenance of Cylindrical Roller Bearings includes proper lubrication, routine inspections, and ensuring that the bearings are correctly installed and aligned to prevent premature wear and failure.

While Cylindrical Roller Bearings are primarily designed for radial loads, certain types can handle limited axial loads depending on their design and application requirements.

Cylindrical Roller Bearings are used in applications that require high radial load capacity and minimal friction, such as heavy machinery, automotive applications, and industrial gearboxes.

Cylindrical Roller Bearings offer high load capacity, low friction, and the ability to accommodate high-speed rotations, making them ideal for demanding industrial applications.

We use only the highest-grade raw materials and cutting-edge technology. Our bearings are checked on several parameters before shipment to ensure they meet industry standards.

Our Products

Spherical roller bearings

Plain Spherical bearings

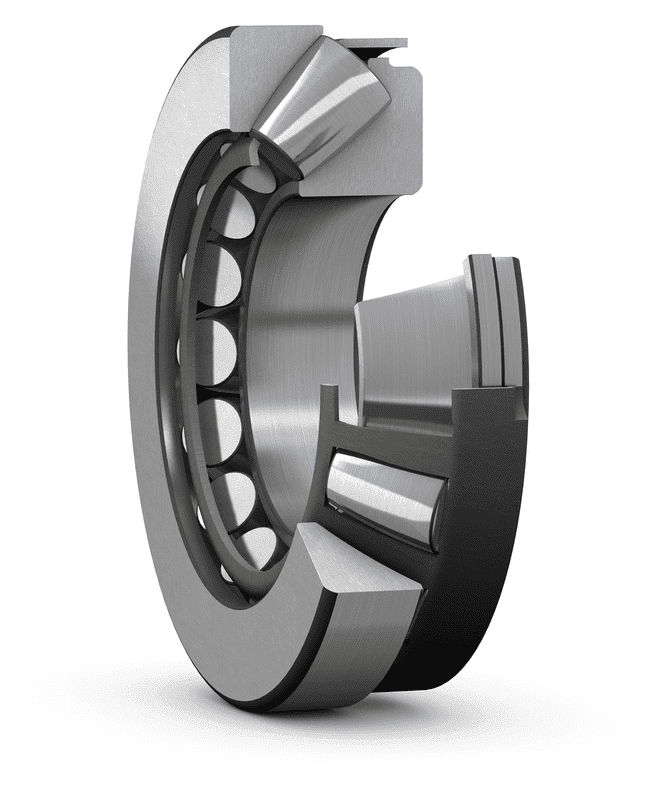

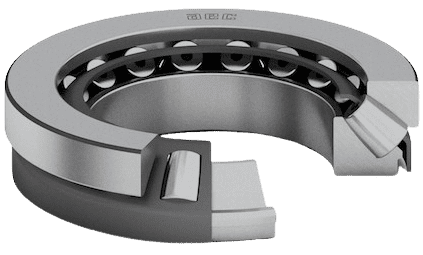

Thrust Spherical bearings

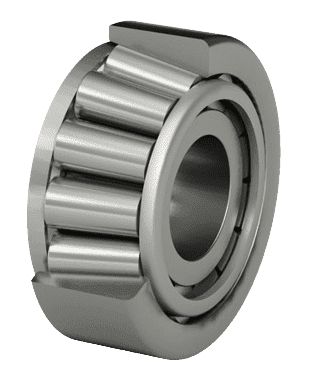

Taper Rolling Bearings

Ball bearings