KEC: Renowned Mining Equipment Bearings Manufacturer & Exporter

Ball Bearings

Applications

- Automotive

- Aerospace

- Industrial Machinery

- Consumer Electronics

- Medical Equipment

- Renewable Energy

- Automotive

- Railways

Contact For OEM supply

An Original equipment manufacturer (OEM) is a company that supplies components that are used in th production of goods by other manufacturers.

At KEC BEARINGS, we are leading Mining Equipment Bearing Manufacturers, dedicated to delivering high-quality bearings that ensure outstanding performance and reliability. Made from premium bearing steel, our mining equipment bearings provide durability and longevity across various applications.

These bearings are essential in machinery, reducing friction and enhancing efficiency while supporting both radial and axial loads. We offer options with steel and brass cages to meet different operating conditions.

As trusted Mining Equipment Bearing Suppliers and Mining Equipment Bearing Exporters, each bearing undergoes rigorous quality control to meet international standards. We take pride in exceeding customer expectations across mining, construction, and heavy machinery sectors.

Our commitment to excellence positions us as a reliable Mining Equipment Bearing Exporter, providing products that perform consistently well, even in challenging environments. By choosing KEC BEARINGS, you ensure unmatched reliability from a trusted Mining Equipment Bearing Supplier. Trust us for exceptional quality and performance in mining equipment bearings.

Choose KEC for the Premier Mining Equipment Bearings Manufacturer.

Our bearings are crafted from premium-grade bearing steel, guaranteeing exceptional durability and performance. With options for both steel and brass cages, we offer flexibility to cater to the varied demands of different operating environments. As a leading Mining Equipments Bearing Manufacturer, we ensure that each bearing undergoes rigorous quality control to meet and surpass international standards.

This steadfast dedication to quality establishes us as a reliable Mining Equipments Bearing Exporter and supplier, providing trustworthy products that maintain consistent performance even in challenging conditions. Opt for our Mining Equipments Bearings for unparalleled reliability and efficiency from a reputable Mining Equipments Bearing Supplier. Our commitment to excellence makes us the preferred choice among Mining Equipments Bearing Manufacturers in the industry.

7000 Angular Contact Ball Bearings & 7200 Angular Contact Ball Bearings

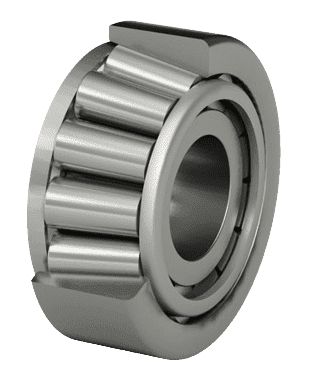

30200 Tapered Roller Bearings & 30300 Tapered Roller Bearings

51100 Thrust Ball Bearings & 51200 Thrust Ball Bearings

22200 Spherical Roller Bearing

23028 Spherical Roller Bearing

24034 Spherical Roller Bearing

32206 Taper Roller Bearing

22300 Taper Roller Bearing

23100 Taper Roller Bearing

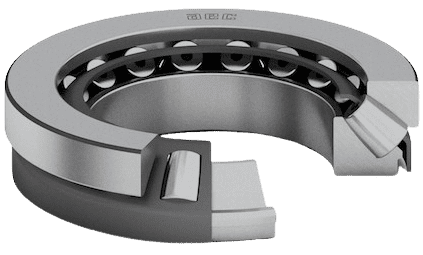

51102 Thrust Ball Bearing & 51306 Thrust Ball Bearing

51204 Thrust Ball Bearing

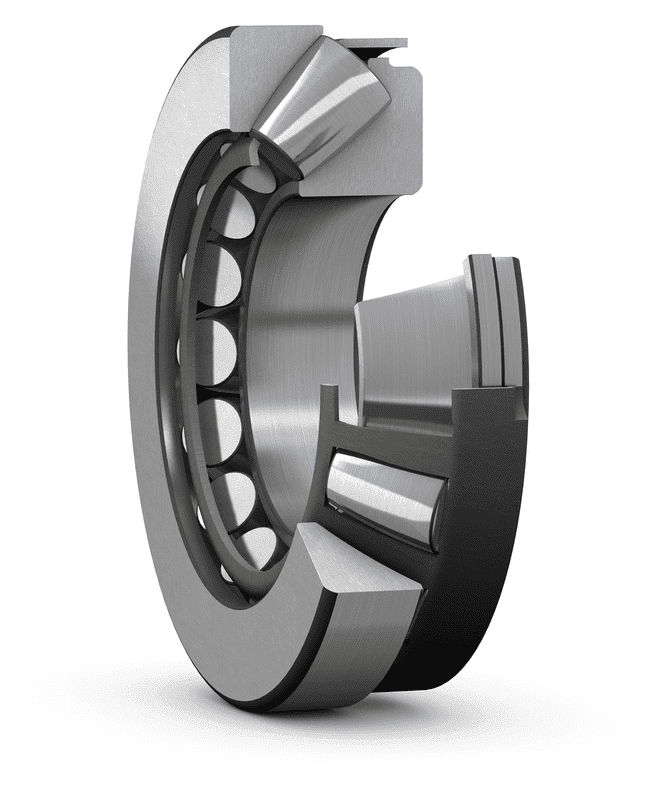

81105 Roller Thrust Bearing & 81212 Roller Thrust Bearing

Key Features

Self-Aligning Capability

Automatically adjusts to misalignment.

High-Quality Materials

Made from premium steel for superior performance.

Robust Design

Suitable for harsh environments and demanding applications.

Long Service Life

Enhanced durability and resistance to wear.

Low Friction

Reduces operating temperature and improves efficiency.

Discover detailed specifications, features, and benefits of our entire range of products by downloading our comprehensive brochure. Get in-depth information on applications, technical data, and more to help you make the best decision for your needs.

Toughness with Precision Guaranteed

Leading Choice: Sugar Mills Industry

Get answers to common inquiries about bearings in mining equipment, focusing on their applications, specifications, and maintenance procedures.

The most commonly used equipment includes excavators, bulldozers, drill rigs, haul trucks, and conveyor systems.

Selection depends on factors like the type of mineral being extracted, the mining method, site conditions, and production goals.

Key safety considerations include proper training, regular maintenance, use of personal protective equipment (PPE), and adherence to safety protocols.

Maintenance schedules vary by equipment type and usage but typically involve daily inspections and regular servicing based on operational hours.

Recent advancements include automation, improved fuel efficiency, enhanced safety features, and the integration of data analytics for performance monitoring.

Our Products

Spherical roller bearings

Plain spherical bearings

Thrust spherical bearings

Taper Rolling Bearings

Ball bearings