KEC: Top-Quality Steel Plants Bearing Manufacturer & Exporter

Ball Bearings

Applications

- Automotive

- Aerospace

- Industrial Machinery

- Consumer Electronics

- Medical Equipment

- Renewable Energy

- Automotive

- Railways

Contact For OEM supply

An Original equipment manufacturer (OEM) is a company that supplies components that are used in th production of goods by other manufacturers.

At KEC BEARINGS, we are recognized as leading Steel Mills Bearing Manufacturers, committed to producing high-quality bearings that deliver outstanding performance and reliability. Our steel mills bearings are crafted from premium bearing steel, ensuring they provide durability and longevity across various applications. KEC BEARINGS is your reliable Steel Mills Bearing Manufacturer, supplier, and exporter for optimal performance.

Steel mills bearings are essential components in machinery, significantly reducing friction and improving the efficiency of moving parts. Designed to support both radial and axial loads, our steel mills bearings are versatile and suitable for a wide range of industrial and commercial uses. We offer options with both steel and brass cages, tailored to different operating environments and specific requirements. With our rigorous quality control and dedication to excellence, KEC BEARINGS stands out as a top-tier Steel Mills Bearing Manufacturer.

As a trusted Steel Mills Bearing Supplier and Steel Mills Bearing Exporter, each bearing produced by KEC undergoes rigorous quality control processes to ensure compliance with international standards. We take pride in delivering products that exceed customer expectations. Whether you need steel mills bearings for automotive, aerospace, industrial machinery, or any other application, KEC BEARINGS is your reliable Steel Mills Bearing Manufacturer, supplier, and exporter for optimal performance.

Why Go with KEC, the Industry's Leading steel plant bearing manufacturer?

This commitment to quality establishes us as a trusted Steel Mills Bearing Exporter and supplier, delivering reliable products that consistently perform in challenging conditions. Choose our bearings for unmatched reliability and performance from a reputable Steel Mills Bearing Supplier. Our focus on quality makes us the preferred choice among Steel Mills Bearing Manufacturers in the industry.

6001 ZZ Deep Groove Ball Bearing

6203 Deep Groove Ball Bearing

6305 Deep Groove Ball Bearing

22205 Spherical Roller Bearing

23028 Spherical Roller Bearing

24034 Spherical Roller Bearing

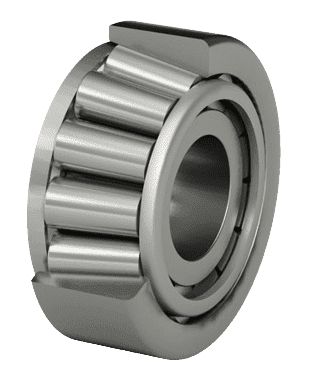

32206 Taper Roller Bearing

32010 Taper Roller Bearing

33008 Taper Roller Bearing

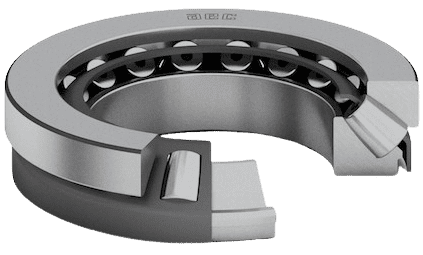

51102 Thrust Ball Bearing & 51306 Thrust Ball Bearing

51204 Thrust Ball Bearing

81105 Roller Thrust Bearing & 81212 Roller Thrust Bearing

Key Features

Self-Aligning Capability

Automatically adjusts to misalignment.

High-Quality Materials

Made from premium steel for superior performance.

Robust Design

Suitable for harsh environments and demanding applications.

Long Service Life

Enhanced durability and resistance to wear.

Low Friction

Reduces operating temperature and improves efficiency.

Discover detailed specifications, features, and benefits of our entire range of products by downloading our comprehensive brochure. Get in-depth information on applications, technical data, and more to help you make the best decision for your needs.

Toughness with Precision Guaranteed

Most Popular: Steel Plants Industry

Find answers to common questions about our steel plant’s bearings, including their applications, specifications, and maintenance.

Steel plant bearings are typically made from high-quality bearing steel, with options for steel or brass cages to suit different operating conditions.

Selecting the appropriate bearing depends on factors like load capacity, speed, operating environment, and the specific machinery requirements.

High-quality bearings offer improved durability, reduced maintenance costs, and enhanced performance, which are vital for minimizing downtime in steel production.

Regular inspections should be conducted every few months or according to the manufacturer’s guidelines to ensure optimal performance and early detection of wear.

Yes, proper lubrication is essential for reducing friction, dissipating heat, and prolonging the life of bearings in steel mills.

Our Products

Spherical roller bearings

Plain spherical bearings

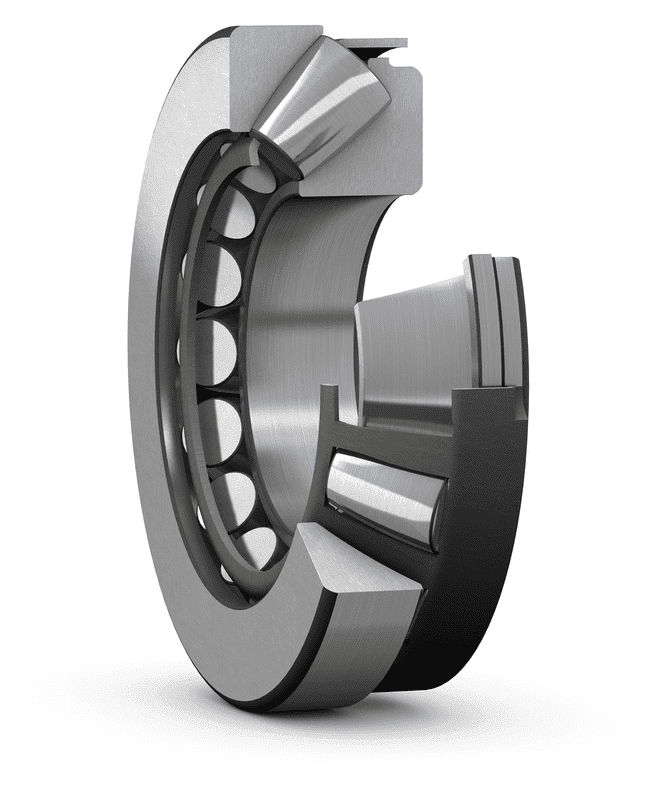

Thrust spherical bearings

Taper Rolling Bearings

Ball bearings