KEC - Leading firm for Taper Roller Bearings India

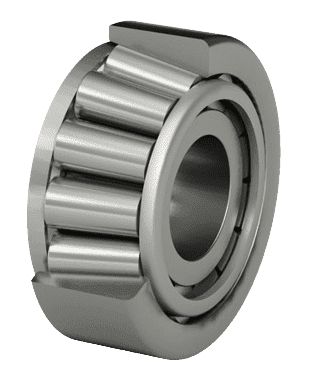

Taper Roller Bearings

Applications

- Mining and Quarrying Equipment

- Construction Machinery

- Steel Industry

- Power Generation

- Agricultural Machinery

- Marine Applications

- Automotive

Contact For OEM supply

An Original equipment manufacturer (OEM) is a company that supplies components that are used in th production of goods by other manufacturers.

Tapered roller comes with the capacity to withstand significant rotational pressures among the various types of roller bearings. It has strong velocity and the capability to withstand significant circumferential pressures too. When it comes to this kind of roller bearings, KEC should be your number one Taper Roller Bearing Company choice. The company mission is to provide the best quality bearing goods service that also contains value and assurance to the clients to offer you profits that go beyond the mechanism.

Taper roller bearings India are available to smoothly handle substantial combined loads without any problems in both the radial and longitudinal dimensions. Additionally, they can easily handle rotational weights directed in only a single direction. Because of their flawless designs, rolling motion can be facilitated by our company’s Taper Roller bearings, which are designed to avoid forcing the rollers to skid while doing so.

Why partner with us?

KEC is an experienced and reputed taper roller bearing company in India and has never moved from its commitment to the principle that places quality before the consumer’s needs. Our company carries procedures following the quality standards that have been outlined, with an increased emphasis on protection. Our dedication to every one of our consumers is to develop high-quality products that are win-win situations.

KEC is an experienced and reputed taper roller bearing company in India and has never moved from its commitment to the principle that places quality before the consumer’s needs. Our company carries procedures following the quality standards that have been outlined, with an increased emphasis on protection. Our dedication to every one of our consumers is to develop high-quality products that are win-win situations.

32224 Taper Roller Bearings

Tapered Roller Bearings 32230

32234 Taper Roller Bearings

32305 Taper Roller Bearing

32307 Tapered Roller Bearings

32313 Taper Roller Bearing

32314 Taper Roller Bearing

32316 Taper Roller Bearing

32318 Taper Roller Bearing

32324 Taper Roller Bearing

32328 Taper Roller Bearing

32948 Taper Roller Bearing

33013 Taper Roller Bearing

Key Features

Self-Aligning Capability

Automatically adjusts to misalignment.

High-Quality Materials

Made from premium steel for superior performance.

Robust Design

Suitable for harsh environments and demanding applications.

Long Service Life

Enhanced durability and resistance to wear.

Low Friction

Reduces operating temperature and improves efficiency.

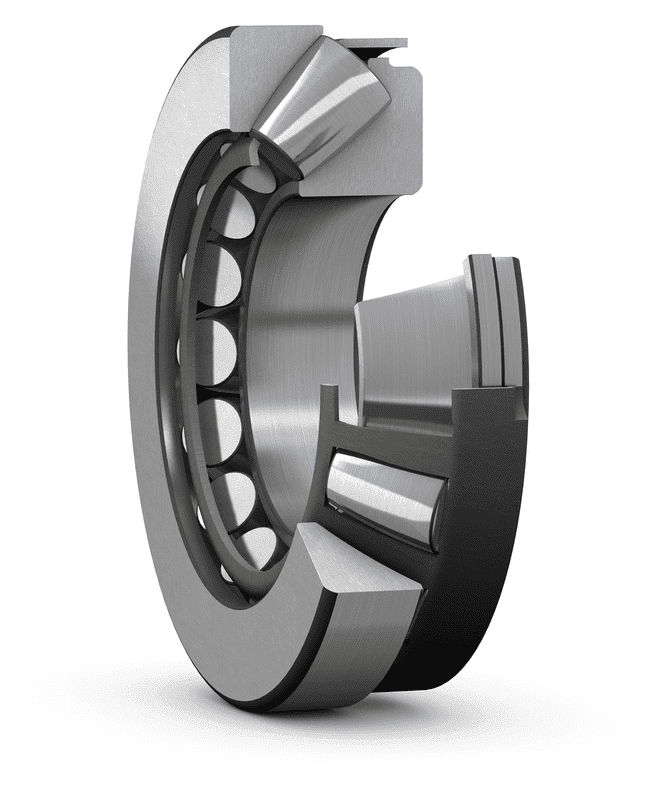

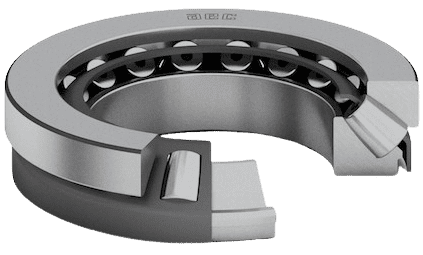

Single Row

Double Row

Discover detailed specifications, features, and benefits of our entire range of products by downloading our comprehensive brochure. Get in-depth information on applications, technical data, and more to help you make the best decision for your needs.

Toughness with Precision Guaranteed

Checkout Frequently Asked Questions

Taper Roller Bearings are used in applications that require the management of combined loads (both radial and axial). They are commonly found in automotive, aerospace, and heavy machinery industries due to their high load capacity and reliability.

KEC Taper Roller Bearings are crafted from premium bearing steel and are available with both steel and brass cages, ensuring optimal performance and durability.

The tapered design of the bearings allows them to efficiently handle both radial and axial loads. The larger contact area of the rollers and raceways provides better load distribution and reduces stress, resulting in longer bearing life.

Benefits include high load capacity, precision engineering, enhanced durability, and reliability. Our bearings are designed to perform in demanding environments, providing long-term value and reducing maintenance needs.

Regular maintenance of taper roller bearings includes proper lubrication, regular inspections, and timely replacements if any wear or damage is detected. Following these practices ensures optimal performance and longevity.

Our Products

Spherical roller bearings

Plain Spherical bearings

Thrust Spherical bearings

Taper Rolling Bearings

Ball bearings